In recent yrs, area of elements science has seen remarkable advancements, paving the way in which for impressive applications and products that were once deemed impossible. Among these kinds of pioneering materials, advanced ceramics have emerged while a frontrunner, defining what is possible across various sectors. With their distinctive properties, such as exceptional hardness, thermal resistance, and lightweight nature, advanced ceramics are changing sectors from consumer electronics to aerospace.

Even as get deeper in the complex world of advanced ceramics, it becomes crystal clear that their possible reaches far past traditional uses. These kinds of materials are not really only enhancing the performance of present technologies but also enabling groundbreaking innovations in fields like biomedical engineering plus renewable energy. By area code new possibilities, advanced ceramics are set in order to play an important role in shaping some sort of sustainable and impressive future for ages to come.

What are Advanced Ceramics?

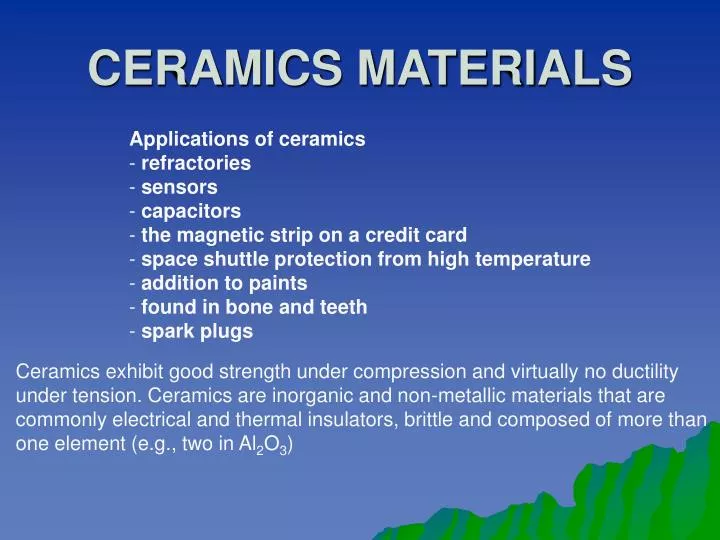

Advanced ceramics are materials that will exhibit superior qualities when compared with traditional ceramics. These materials are usually often engineered in order to have enhanced mechanised strength, thermal stability, and resistance in order to wear and corrosion. They may be formulated in order to achieve specific characteristics that make them suitable for a new wide range involving applications, from aeronautical to biomedical job areas.

One of the understanding features of advanced ceramics is their capacity to withstand serious conditions while maintaining functionality. This includes great heat and pressures, along with exposure to intense chemicals. As the result, they enjoy a critical position in industries that will demand reliability in addition to durability in their parts, such as gadgets, energy production, in addition to manufacturing.

The production associated with advanced ceramics involves superior techniques like powdered processing, sintering, and additive manufacturing. These types of processes enable the particular creation of complicated shapes and complex microstructures that are not possible with traditional procedures. As innovation goes on in this line of business, advanced ceramics are setting up new standards, pushing the boundaries involving what materials can perform in modern technologies.

Software in Technology

Advanced ceramics make significant breakthroughs in various technological sectors, playing an important role inside the enhancement of modern devices and systems. Just about the most prominent applications is in the field of electronic devices, where materials such as silicon carbide in addition to aluminum oxide are usually used to generate insulating substrates, capacitors, and piezoelectric equipment. These ceramics improve thermal conductivity in addition to electrical performance, increasing the efficiency and even reliability of consumer electronics, telecommunications, and energy systems.

In the sphere of aerospace in addition to automotive industries, advanced ceramics are employed for his or her lightweight and high-temperature resistance characteristics. Pieces such as turbine blades, brake dvds, and thermal defense systems enjoy the strength-to-weight ratio of ceramics, enabling better fuel efficiency and improved performance under serious conditions. This application not only enhances the durability of parts but additionally contributes substantially to reducing general vehicle weight plus emissions.

Another vital area where advanced ceramics usually are making a direct effect is in the medical industry. Ceramic materials are generally used in enhancements, prosthetics, and dental applications due to their biocompatibility and mechanical attributes. Innovations for instance bioactive ceramics promote structure growth and integration, providing effective alternatives for orthopedic and even dental surgeries. Like technology continues to progress, the potential associated with advanced ceramics in healthcare is vast, paving the way for improved patient outcomes and standard of living.

Great things about Advanced Ceramics

Advanced ceramics offer exceptional mechanical properties, generating them vital within a variety involving applications. Their large strength and strength allow them to be able to withstand extreme circumstances, including great heat plus harsh environments. This kind of durability causes them to be excellent for use inside aerospace, automotive, plus industrial applications in which reliability and overall performance are critical. In addition, their lightweight nature contributes to increased efficiency in these types of sectors.

Another significant advantage of advanced ceramics is their excellent put on and corrosion level of resistance. Unlike many traditional materials, advanced ceramics can maintain their sincerity in the presence of aggressive chemical compounds and abrasive elements. This characteristic stretches the lifespan regarding components made by these materials in addition to reduces maintenance fees as time passes. As industries strive for long-lasting plus cost-effective solutions, advanced ceramics always stand out and about as a preferred choice.

Moreover, advanced ceramics will also be recognized for their own electrical and energy insulation properties. This particular makes them suited for electronic applications where preventing electric conduction is essential. Their ability to withstand great heat without degrading further enhances their appeal in sectors like electronic devices and energy. As technology advances, typically the demand for materials that can conduct under extreme problems keeps growing, solidifying the particular role of advanced ceramics in innovative remedies.

Producing Operations

The manufacturing functions of advanced ceramics will be critical to attaining their unique properties plus applications. These functions typically begin along with the preparation associated with high-purity unprocessed trash, including oxides, carbides, and nitrides. These elements are carefully picked and processed to ensure consistent top quality. Once the natural materials are found, they are frequently combined into appropriate mixtures and put through to treatment such as milling in addition to blending to obtain a homogeneous dust necessary for subsequent actions.

Pursuing the powder prep, shaping may be the up coming key stage in the manufacturing process. Techniques such because uniaxial pressing, isostatic pressing, and go casting are used to form the particular ceramic into ideal shapes. Each framing method offers specific advantages, such seeing that enhanced density or even intricate geometries. Just after shaping, the formed ceramic undergoes drying out to remove any dampness content, which is definitely vital to stop flaws during the firing process.

The final stage involves sintering, wherever the shaped porcelain is heated to be able to elevated temperatures found in a controlled atmosphere. Sintering facilitates compound bonding and densification, significantly enhancing mechanised strength and thermal stability. The very careful control of temperature and atmosphere in the course of this stage will be essential to avoid issues such like deformation or undesirable phases which could agreement the performance of the final merchandise. Ultimately, the mix of these manufacturing techniques results in advanced ceramics with exceptional properties fitted to a broad range of business applications.

Challenges and Limits

In spite of the promising programs and properties associated with advanced ceramics, several challenges hinder their wide-spread adoption. One significant issue is their very own brittleness. While advanced ceramics exhibit hi-strength plus hardness, luckily they are likely to cracking and catastrophic failure under stress. The lack involving ductility limits their particular use in applications that require effects resistance or sturdiness, prompting researchers to be able to seek approaches to boost their mechanical components.

One more challenge lies throughout benefit manufacturing charges associated with advanced ceramics. The processes included in producing high-purity raw materials, combined with energy-intensive sintering needed to achieve desired densities, contribute to the overall expenses. Read more can be quite an important barrier, particularly inside industries where cost-efficiency is critical. Therefore, ongoing research is usually dedicated to developing more economical production approaches without compromising materials quality.

Finally, advanced ceramics generally face limitations found in terms of scalability. Many existing operations are optimized with regard to small-scale production, helping to make it difficult to range up for industrial applications. As with regard to advanced ceramics grows, ways to enhance production amount while ensuring constant quality remain an area of active analysis. Overcoming these difficulties is essential intended for fully unlocking typically the potential of advanced ceramics in various scientific fields.

Future Trends

As the particular demand for high-performance materials continues to be able to rise, advanced ceramics are usually poised to participate in a crucial role in various industrial sectors. Innovations in control techniques and stuff design are traveling the development of ceramics of which exhibit unparalleled attributes, like increased sturdiness, enhanced thermal balance, and improved conductivity. These advancements may enable their application in harsher conditions, pushing the limits of what will be currently possible inside electronics, aerospace, and even biomedical fields.

Emerging systems, such as ingredient manufacturing and nanotechnology, are expected in order to further revolutionize the particular advanced ceramics landscape. Simply by utilizing these approaches, manufacturers can make complex geometries that will were previously not possible, paving the way in which for customized solutions throughout a wide array of applications. This specific flexibility not simply allows for performance optimization but in addition reduces material waste, aligning with sustainability goals in today's manufacturing processes.

Additionally, typically the integration of advanced ceramics with smart technologies is an interesting frontier that pledges to enhance the particular functionality of goods. Typically the incorporation of sensors and data-transmitting features into ceramic elements will result in the development of intelligent systems that can monitor and adjust to their surroundings. This trend will significantly impact areas such as health care, where smart enhancements can provide real-time feedback, and energy, where self-sensing materials can easily lead to more efficient systems.

Case Studies

One significant case in the realm involving advanced ceramics may be the use of silicon carbide in the vehicle industry. Silicon carbide is renowned for its high energy conductivity and exceptional hardness. These qualities help it become an excellent material for braking mechanism components and motor parts that require strength and heat weight. Major car companies have begun including silicon carbide ceramics into their designs, leading to lighter in weight vehicles with improved performance and energy efficiency. This innovation not just improves typically the car's performance although also plays a part in durability by reducing exhausts.

On the medical discipline, advanced ceramics have changed distinguishly dental implants and even prosthetics. Zirconia, the type of advanced ceramics, is favored for the biocompatibility and aesthetic qualities. Dental pros now utilize zirconia-based materials to make crowns and links that closely look like natural teeth. By providing patients together with strong and creatively appealing dental alternatives, advanced ceramics are drastically improving the standard of oral care. This situation underscores the adaptability of ceramics inside of applications that demand both functionality and aesthetics.

Another impressive illustration can be discovered in the gadgets sector, where advanced ceramics play a huge role in the production of capacitors and insulators. The high di-electric constant and electric powered insulation properties involving barium titanate ceramics make them appropriate candidates for electric components. Companies specializing in electronic devices include adopted these supplies to improve the particular efficiency and reliability of their goods. As technology continues to advance, the demand for top of the line ceramics will most likely grow, further showcasing their indispensable function in the foreseeable future of consumer electronics.

Bottom line

The field of advanced ceramics is poised to play a critical role in healthy diet future technologies and innovations across various industries. With their particular exceptional properties, these types of materials are not really only enhancing present applications but likewise paving the approach for entirely new possibilities. From tail wind to electronics, typically the versatility of advanced ceramics offers approaches to several of the most pressing challenges encountered today.

As research and development carry on to progress, we can expect significant advancements inside the performance and uses of advanced ceramics. Improvements such as biocompatible ceramics for healthcare applications and light and portable materials for vehicle use illustrate the particular breadth of probable. The ongoing hunt for hybrid materials in addition to novel manufacturing methods will likely press the boundaries regarding what these ceramics can achieve.

Ultimately, the future of advanced ceramics is usually bright, promising in order to unlock unprecedented chances for industries plus researchers alike. While we continue to improve and explore typically the capabilities of these components, we move better to realizing a future where their impact is felt across multiple sectors, driving a car progress and enhancing quality of living.